Allseas has launched an ambitious five-year plan to design, develop and deploy a Small modular reactor (SMR) tailored for integration into offshore vessels and for onshore use.

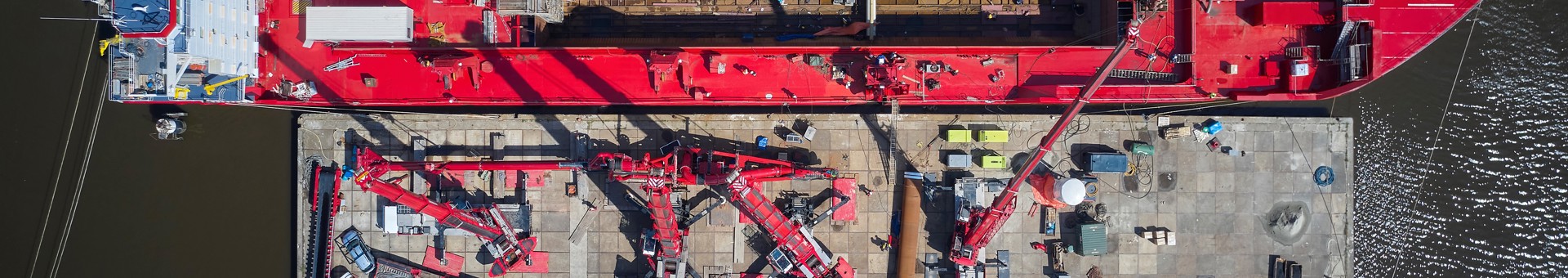

Building on 40 years of engineering expertise in the offshore energy industry, this move into nuclear marks the next bold step – delivering clean, high-performance energy systems to sea and shore.

The maritime sector has a 3% contribution to global CO₂ emissions. Alternative fuels like hydrogen, methanol and ammonia currently face limitations in availability, scalability and cost – particularly for remote, energy-intensive operations. Nuclear offers unmatched energy density, combining zero emissions with stable, scalable power supply.

Onshore, industrial clusters face high energy costs, grid congestion and volatile renewable supply. SMRs can ease grid pressure while providing consistent, carbon-free power and heat – accelerating decarbonisation and boosting industrial resilience and long-term competitiveness.

“As a family-owned company, continuity and preservation for future generations are central to how we work. We’ve built our reputation on turning bold ideas into ground-breaking solutions to meet the offshore industry's evolving needs. That spirit of innovation, grounded in responsibility and reliability, drives everything we do,” says Stephanie Heerema, Project Manager Nuclear Developments at Allseas.

Safety-driven innovation

Allseas has selected High-temperature gas-cooled reactors (HTGRs) in the 25 MWe range, due to their inherently safe characteristics. This fourth-generation reactor technology generates energy without combustion or emissions.

HTGRs are powered by TRISO fuel particles, each representing a sphere with the size of a poppyseed. Each particle contains a uranium oxide core, coated with several advanced protective ceramic layers that securely contain fission products – even under extreme conditions. The technology results in passive safety: the reactor self-regulates and remains stable, keeping temperatures well below critical thresholds. In the unlikely event of malfunction, the system automatically cools down and shuts off without the need for active intervention or external cooling.

Responsible waste management is central to Allseas’ long-term plan. Hence, Allseas is exploring circular approaches, such as the reuse of graphite and reprocessing of spent TRISO fuel, to further reduce environmental impact, ensuring waste management remains a key consideration throughout the SMR lifecycle.

“Delft University of Technology has been working on an inherently safe microreactor based on HTR technology for more than 10 years. We are therefore delighted to contribute to a practical application of this technology,” explains Jan Leen Kloosterman, Professor of Nuclear Reactor Physics and Department Head Radiation Science and Technology, Delft University of Technology.

“NRG PALLAS has been involved in safety demonstration of pebble fuel containing TRISO. This has been successfully demonstrated for several clients in our High Flux Reactor in Petten. TRISO fuel has proven in several countries to be robust and safe under various conditions,” says Frederic Blom, Manager Nuclear Compliance and Projects at NRG PALLAS, a prominent Dutch nuclear authority and research institute specialising in nuclear energy solutions and medical isotopes.

“Nuclear provides a true zero carbon solution for maritime without compromising on performance, Lloyd’s Register is seeing a growing recognition of this in industry and is proud to support Allseas in this ground breaking project,” adds Mark Tipping, Global Power to X Director, Lloyd’s Register, a global authority in maritime safety, providing independent certification and oversight for nuclear propulsion technologies.

Roadmap to delivery

Allseas has set out a clear five-year roadmap. In the first year, we will finalise initial design studies for offshore and onshore use. This will be followed by prototype development and pre-licensing discussions

in consultation with key stakeholders, including:

• Regulators such as the Dutch Authority for Nuclear Safety and Radiation Protection (ANVS), International Maritime Organization (IMO) and International Atomic Energy Agency (IAEA),

• Safety and classification bodies including Lloyd’s Register, and in close collaboration with our research and innovation partners including TNO, NRG PALLAS, TU Delft, and KVNR.

“Our goal is to start production at a dedicated facility by 2030,” adds Stephanie Heerema. “Initial deployment will likely begin on land while offshore regulations are finalised, followed by application on our own vessels and broader industry adoption. This aligns with our own sustainability targets – 30% emissions reduction by 2030, and net-zero operations by 2050.”

“This technology is key to achieve the energy transition and strategic autonomy in the maritime and offshore sector,” says Maarten Tossings, Chief Operating Officer of research and technology organisation TNO. “In parallel, it strengthens the long-term competitiveness of Dutch and European industry.”

Strategic impact for Europe and the Netherlands

“Pioneering this technology offers the Netherlands – as a seafaring nation – the opportunity to develop an innovative global export product and become a leader in net zero shipping,” says Annet Koster, Managing Director, Royal Association of Netherlands Shipowners (KVNR). “It also contributes to Europe’s broader goals of enhancing energy security, boosting industrial competitiveness, and building strategic autonomy.”

“Nuclear is the next frontier, and Allseas is leading the way to deliver safe, clean and reliable offshore and onshore energy,” concludes Stephanie Heerema. “As pioneers of offshore innovation with a can‑do mentality, from single‑lift platform removal to dynamically positioned pipelay, we have a proven track record of turning groundbreaking concepts into reality.”